A Roundup of Our EDM Services: Wire EDM, Sinker EDM, and Drill EDM

At United Centerless Grinding and Thread Rolling, our name doesn’t capture everything we do. If it did, it would be too long to fit on a sign.

Over our decades in business, we’ve continually expanded our capabilities, and one of our most impactful additions has been our EDM services, short for electrical discharge machining. With our wire EDM, sinker EDM, and EDM drilling, we deliver intricate features, machine hard materials, and achieve complex geometries with the same precision our customers have trusted us to provide for more than 60 years.

Traditional Machining vs. EDM Services

EDM offers unique advantages over milling, turning, or grinding that may be surprising to customers who are more familiar with traditional machining. Instead of cutting with a tool, EDM removes material through controlled electrical discharges, though the specific details vary between techniques such as wire EDM and sinker EDM.

Features like sharp corners, thin walls, or tight radii can be difficult or even impossible to achieve with conventional machining methods. In these cases, EDM is the ideal solution.

Wire EDM: Precision Through-Cutting

Our wire EDM services are ideal for cutting contours and through-cutting in conductive materials. With wire diameters as small as 0.004 inches, we can produce radii down to 0.002 inches and hold tolerances down to ± 0.0002”. That precision allows us to create features that would be almost impossible with milling or turning alone, including:

Tight corner radii

High surface finishes

Extremely tight tolerances

Sinker EDM: Complex Cavities, Sharp Internal Corners and More

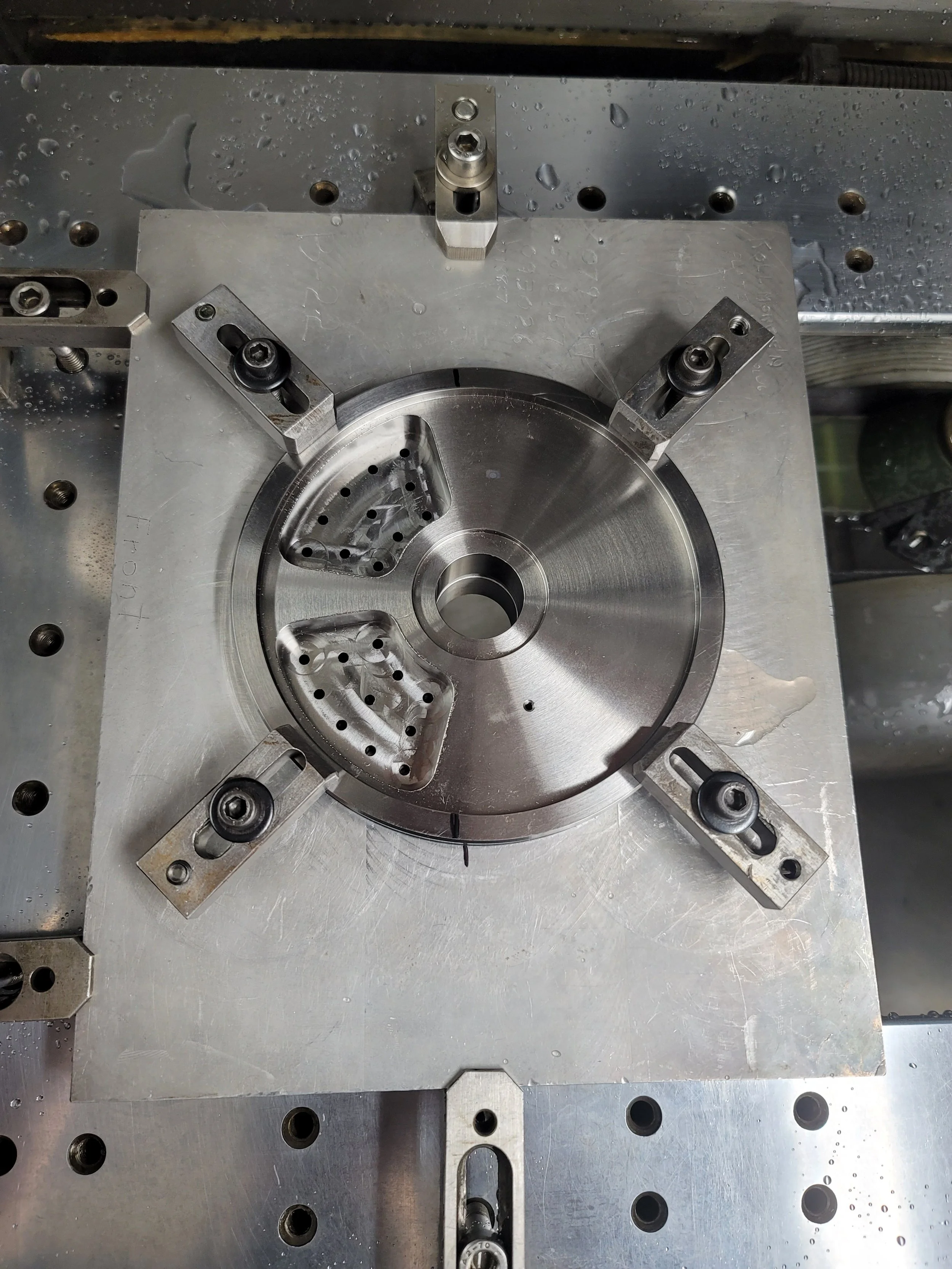

Our sinker EDM services are the latest addition to our capabilities, intended to help us fill gaps in areas where we could not serve our customers with our existing wire EDM services. Our advanced Mitsubishi SG 12 Sinker EDM machine enables fast and efficient operations.

Sinker EDM differs from wire EDM by using a shaped electrode to “sink” into the workpiece. This process is excellent for features such as:

Blind features

3D cavities

Complex geometries

EDM Drilling: Fast, Accurate Holes

Our AgieCharmilles CNC EDM Drill 20 produces through-holes and blind-holes with diameters from 0.5 mm to 3.0 mm, achieving accuracy down to one-thousandth of a millimeter. We often use this capability for hole-popping operations where both precision and repeatability are critical.

EDM at UCGTR: Support, Experience, and More

What sets United Centerless Grinding and Thread Rolling apart is not just the range of our EDM services, but also the support we provide throughout your process. We handle volumes as high as tens of thousands of parts, but we can also assist your path to production.

Our early-stage guidance and design for manufacturing (DFM) advice can help you simplify your designs and ensure your parts are cost-effective. We also create custom fixtures for high-volume efficiencies, and our in-house engineers can help you create drawings and solve your manufacturing problems.

We have more than 70 years of combined EDM experience on our team, and that knowledge allows us to manufacture your parts with maximum efficiency and precision.

Explore All of Our Services

With wire EDM, sinker EDM, and EDM drilling in the same facility, customers can trust all of their EDM projects with a single partner. And, of course, our capabilities extend beyond EDM. From precision centerless grinding to thread rolling services and more, we can meet nearly all of your manufacturing needs.

Request a quote today to experience the precision our EDM services can deliver!