Wire and Sinker EDM Services

Wire EDM and Sinker EDM Shapes More Intricate Parts

What Is Wire EDM, and How Does It Work?

Wire EDM (Electrical Discharge Machining) is an electrothermal machining process. It uses a thin single-strand metal wire that acts as a tool electrode to generate heat to cut a linear line through a metal workpiece. The thin wire creates an intense electrical spark that erodes the part’s material with exacting precision without physical pressure.

We use wire EDM for projects that have intricate tolerances, material stress limitations, and surface finish specifications. The number of passes to cut the workpiece affects tolerance and surface finish. More passes deliver a higher degree of precision and better finishes.

For high-volume projects with material too brittle for stamping, wire EDM offers a viable alternative. We stack work material in flat layers so we can cut through the stack for a high volume of precision parts.

Wire EDM cutting contours any conductive material difficult to shape with conventional machining techniques. Conductive metals include alloys, superalloys, steel, aluminum, brass, bronze, copper, carbon graphite, carbon steel, stainless steel, and titanium.

Wire EDM Capabilities

Consider our wire EDM services. With two AgieCharmilles CUT 200 Sp machines, you get precision cut parts in production runs that range up to tens of thousands of pieces.

Our EDM drill or hole popper is the AgieCharmilles CNC EDM Drill 20. It can EDM through holes and blind holes from a range of 0.5 mm to 3.0 mm in diameter. It is accurate up to one-thousandth of a millimeter.

As an AS9100D and ISO9001:2015 registered shop, we monitor and measure quality throughout the grinding process to meet your critical specifications and quality documentation.

Get Your Quote

Use our simple contact form or call either—

860-289-2987

888-570-9496 toll-free

If you’re looking for an EDM machine shop to shape your highly regulated medical or aerospace components, consider our know-how and get a quote.

We cut and contour your parts with when your specifications require wire EDM tolerances—

intricate tolerances within ± 0.0002”

mirror-like surface finishes

small corner radiuses

A Wire EDM and Sinker EDM Company – United Centerless Grinding & Thread Rolling

We’re a nationwide provider of both sinker and wire EDM machining in addition to grinding precision components for more than 500 manufacturers across the United States.

Based in East Hartford, CT, our shop gives you 55 plus years of experience shaping aerospace parts. For more than 25 years, we used wire EDM to make medical parts in addition to our tools.

As an AS9100D and ISO9001:2015 registered shop, our quality assurance team monitors and measures tolerances throughout the forming process to meet your critical specifications and quality documentation.

Our wire EDM capabilities include—

.004 diameter wire to .010 diameter wire

+/- .0002″ tolerances

Parts up to 16″ thick (machine travels: 23.6″ x 15.7″ x 16.5″; maximum workpiece dimensions: 41.3” x 32.3” x 16.3”

Angle taper up to 20 degrees

Small wire burning

Four-axis burns— EDM Drill 20 can make through holes and blind holes from 0.1mm – 3.0mm diameter. It can hold tolerances of +/-.0002”.

Multiple setups—For parts that require features going in more than one direction, we can burn vertical and then turn it lengthwise for a horizontal burn.

Production jobs – Our production runs range in quantity and lot sizes can be up to tens of thousands of parts.

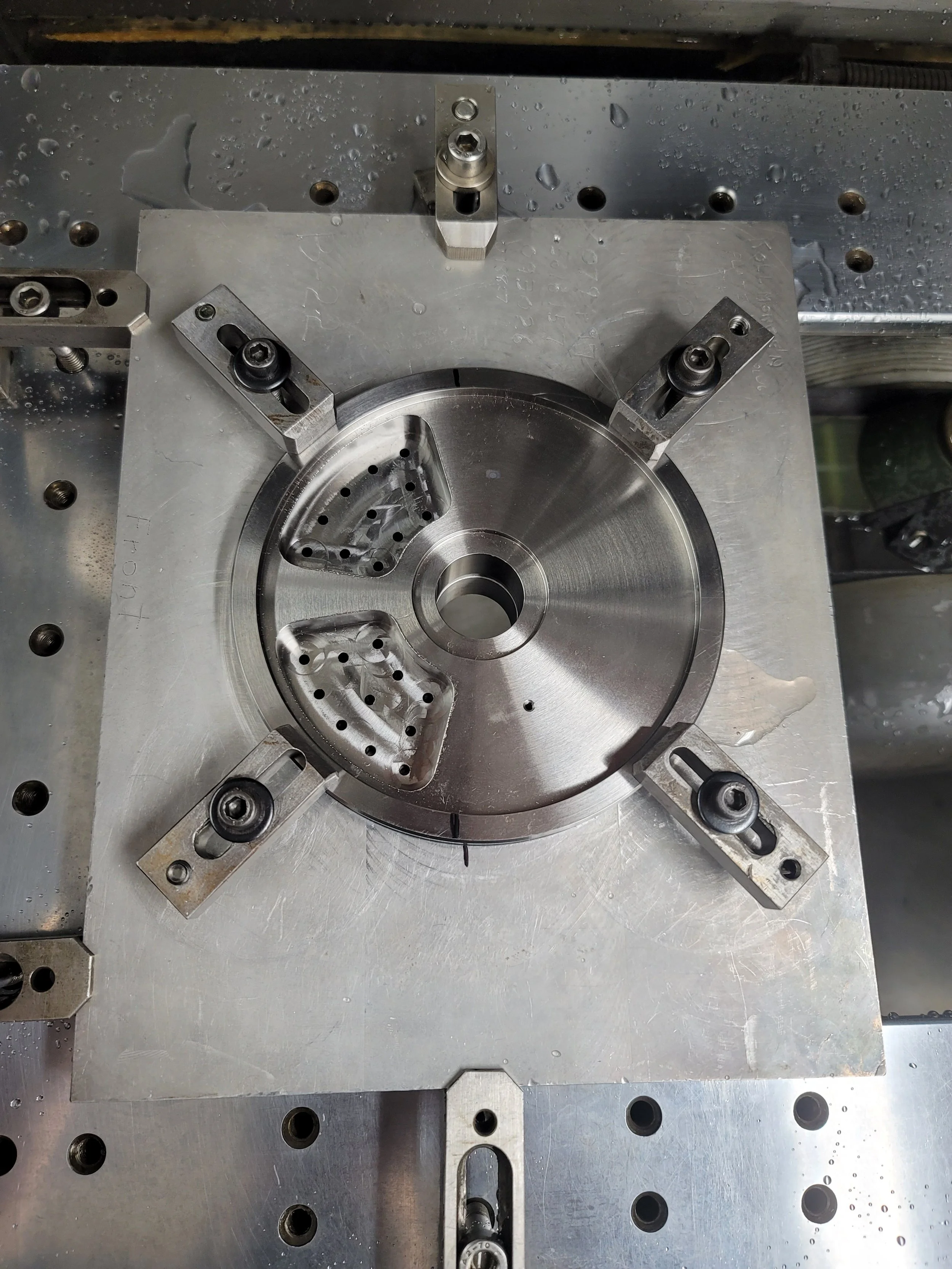

Specialized fixtures— We design and make custom fixtures to hold parts in ways to make unique cuts.

ESPRIT® high-performance CAM system

F–Tool clamping system by EROWA

Precise shape to shape location and fitting

Solidworks CAD program compatibility

Job sizes from 1 to 1,000,000 pieces

Sinker EDM Services at United Centerless Grinding

United Centerless Grinding offers sinker EDM services to support complex machining needs with exceptional precision. Sinker EDM is ideal for creating blind features, intricate geometries, and sharp internal details that cannot be achieved with wire EDM or traditional machining methods. It also excels at machining hardened materials such as steel, titanium, and specialty alloys.

With sinker EDM, along with our wire EDM and EDM drilling capabilities, we provide a complete range of EDM solutions in one shop. This allows us to handle a wide variety of projects efficiently and cost-effectively, helping our customers reduce vendor coordination and streamline production. From prototypes to production runs, our team delivers the accuracy and quality you can count on.